Everything About the Global Chip Shortage

The global chip shortage is more severe than you might assume.

Silicon chips are clearly an important element of the machinery that keeps the world turning, but in 2020, a number of events conspired to put the whole chip business in jeopardy. Much of the world shut down as Covid-19 reared its ugly head and wreaked havoc, but Coronavirus wasn’t the main cause of the problems that followed.

Poor planning, competition amongst various industries for the attention of chip producers, and even natural calamities all had a role in the worldwide chip deficit – in summary, the global chip shortage is considerably more complicated than you might think.

Table of Contents

What is a Chip?

It’s what gives electrical devices their intelligence. The chip is made of a substance that “semi-conducts” electricity and performs a number of functions. Memory chips are simple data storage devices that are traded like commodities. Logic chips, which run programmes and serve as a device’s brain, are more complicated and expensive. These are frequently labelled as Apple or Nvidia, although.

What are the Factors of these Crisis?

Looking back, it’s tough to pinpoint one or two causes for the chip scarcity because it was caused by a slew of issues colliding at the wrong time. However, according to Mario Morales, Program Vice President of the semiconductor group at analysis firm IDC, there was a lack of incentive for silicon chip producers to develop enough foundries to satisfy automakers and others. Nobody, according to Morales, is investing in “legacy technology,” which, despite its age, continues to play a significant role in many industries.

Original equipment manufacturers (OEMs) in the automotive industry “cancelled orders from a lot of the supply chain” during the pandemic, he stated. “So, a lot of disgruntled suppliers found other markets that were still doing well despite the pandemic.”

Original equipment manufacturers (OEMs) in the automotive industry “cancelled orders from a lot of the supply chain” during the pandemic, he stated. “As a result, many frustrated suppliers sought out other markets where business was still booming despite the pandemic.”

However, the issues can be traced further back in time. The US, for example, imposed trade restrictions on China in the fall of 2018. As a result, Huawei, one of China’s largest smartphone manufacturers, placed large orders for chips prior to the imposition of the sanctions. In order to avoid being left behind, Apple and others followed suit – and then the epidemic struck.

It’s unsurprising that pandemic lockdowns contributed to the silicon shortage, but they also had an impact on other areas. Chip-based technology is used in almost anything that has a battery or plugs into a wall outlet.

Smartphones continue to be the most popular electronic product on the planet, thus demand was high, and crypto fans and businesses snapped up graphics processing units (GPUs).

What are the Other Factors?

A number of other underlying variables also had a role in the chip shortage, including the complexity of goods like semiconductors.

The company’s microprocessors, according to Craig Barrett, a former Intel executive, are the most sophisticated machines ever created by man. Because the process is so delicate, semiconductor manufacturing rooms are cleaner than hospital operating rooms. They allow 10,000 particles of air pollution per cubic meter of air in an operation room. They only allow 10 per cubic meter in a room where a semiconductor is produced.

Whether building a semiconductor is simple or complex, the process costs billions of dollars and takes a long time. And if you’re even a fraction off in the process, you’ll almost certainly lose out to a competitor.

From start to finish, making a chip takes around three months and involves multimillion-dollar machinery. As you take a silicon wafer and turn it into a transistor to power your computer, smartphone, or other smart device, you’ll need molten metal and lasers.

Finally, a number of circumstances beyond the semiconductor industry’s control had a role. The shortfall was exacerbated by power outages in Texas, where the majority of the United States’ chip manufacturing is done, and dryness in Taiwan.

Due to government orders, TSMC, the world’s largest semiconductor manufacturer, had to reduce its water usage (which is essential for chip production). Taiwan accounts for more than 60% of global chip foundry income, but the country has been unable to maintain its typical output.

Why is it hard to compete?

Advanced logic chip manufacturing necessitates extreme precision as well as large long-term bets in a rapidly changing area. Plants cost billions of dollars to construct and equip, and they must operate continuously to recoup their costs. But it doesn’t stop there. A factory also consumes a lot of water and electricity, and it’s vulnerable to even minor outages, whether they’re caused by natural disasters or human error.

What are the Impacts on Prices?

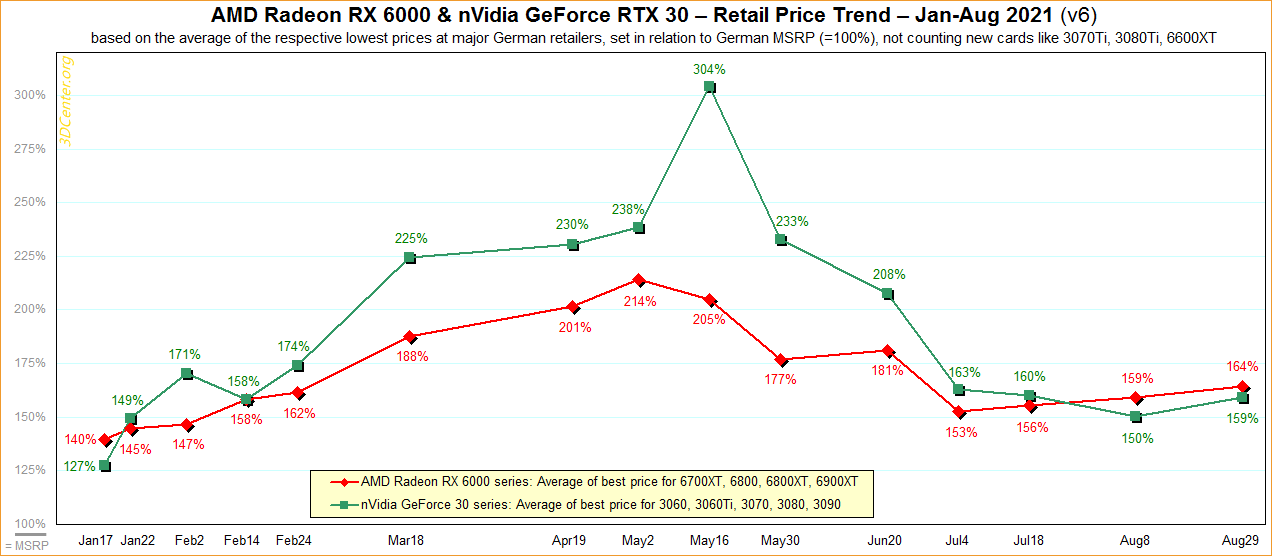

Several other products have grown more expensive as a result of the scarcity, in addition to the potential price hike on smartphones. Since the global chip scarcity began, GPU and CPU prices have risen, with the latter costing up to 50% more than MSRP in most regions, according to some analysts.

The price of GPUs climbed 14 percent from March to May 2021, with Nvidia’s RTX 3060 and RTX 3080 GPUs selling for triple their MSRP and RX 6700 XT or RX 6900 XT GPUs retailing for double their MSRP.

Scalpers, supply chain difficulties, and distributors playing hardball are the three main factors that have contributed to the surge in GPU and CPU price hikes.

Distributors are essentially compelling merchants to buy bundles of items, despite the fact that they have little control on CPU and GPU pricing. Simply put, they’re informing shops that a specific CPU or GPU is only accessible if they also purchase X,Y, and Z. As a result, retailers raise the price of the GPU or CPU to compensate for the additional products they had to purchase merely to get the GPU or CPU they required. Alternatively, you’ll find businesses attempting to sell bundles to customers who don’t require them – a trickle-down effect that isn’t helping the current chip scarcity.

There’s more to it, though. Fabrication plants (fabs) can only create and provide a certain number of chips. Nvidia and Advanced Micro Devices (AMD) suppliers Samsung and Taiwan Semiconductor Manufacturing Company (TSMC) are currently unable to create any more GPUs. Furthermore, issues with substrates, raw materials, GDDR memory, and components persist. That’s also why GPU prices have risen more rapidly than CPU prices.

Who is it Affecting?

Automakers have been effectively paralyzed for more than a year, and the situation is certain to worsen. A new Covid outbreak in Southeast Asia, where most of the semiconductor fabrication for US automobiles is done, might affect the industry even harder next year.

Due to the epidemic, production in countries like Vietnam, the Philippines, and Malaysia was halted, yet US automakers rely significantly on those countries to keep their production lines running, as home-grown fabs account for only 12.5 percent of chip manufacture.

Consumer electronics manufacturing is another industry that is hurting. For example, Apple supplier Hon Hai Precision Industry warned that roughly 10% of its shipments might be disrupted. Meanwhile, Xiaomi announced that due to a global chip scarcity, the price of its devices would rise.

According to the most recent figures, smartphone sales are down 6% year over year, owing to slowed and, in some cases, discontinued production. Furthermore, chip manufacturers are raising their pricing to avoid over-ordering, and it remains to be seen how this will affect the price of smartphones next year.

Smartphone makers such as Samsung and Apple escaped the first wave of the microprocessor shortage because they anticipated it much sooner than the car industry – but certain concerns remain.

The auto industry, among others, is catching up. “Smartphone companies benefited from the additional capacity left behind by automotive businesses,” says Syed Alem of Accenture. “As a result, the automotive sector had a chip shortage when demand for automobiles surged faster than they anticipated.”

“There is severe competition for semiconductor supplies now that the automotive sector and others are coming up and starting to recapture the capacity they had given up.” This has put a strain on smartphone chip supply.”

Due to pent-up demand and a more positive consumer attitude, global smartphone sales increased by 26% in the first quarter of 2021. Chipmakers, on the other hand, are unable to fulfil demand, and this is unlikely to change before the end of the year.

Also Checkout: Sony has filed a patent for the PlayStation Mobile Controller